The steel industry is one of the most important industries in the world. It is responsible for producing the raw material that is used in a wide range of products, from buildings and bridges to cars and ships.

The industry employs millions of people around the world and has a significant impact on the global economy. There are many different types of steel, each with its own unique properties and applications.

In this blog post, we’ll take a closer look at some of the most common types of steel to see what makes them so special.

From carbon steel to stainless steel, there’s sure to be a type of steel that’s perfect for your needs. So let’s dive in and learn a little more about the different types of steel!

five Most Common Types Of Steel?

1-Carbon Steel

Carbon steel is one of the most commonly used types of steel. It is a popular choice for many applications because it is strong and durable, yet relatively inexpensive compared to other types of steel.

The main component of carbon steel is iron, which makes up between 90-95% of its composition.

This type of steel can be heat-treated to increase its strength and hardness, making it ideal for many industrial uses such as automotive parts and tools.

Carbon Steel types

When we talk about Carbon Steel, there are two main types to consider: Low Carbon Steel and High Carbon Steel.

Low carbon steel

Low-carbon steel has a slightly lower amount of carbon – typically 0.05-0.30% – than high-carbon steel which is usually around 0.60%.

This results in low-carbon steel being more ductile and malleable than its High Carbon counterpart;

it can be formed into complex shapes without becoming brittle or cracking.

High Carbon steel

High Carbon steel is much harder and stronger than Low Carbon steel, but it is also less ductile and malleable due to the higher amounts of carbon present within its composition (around 0.60%).

It has excellent wear resistance properties, making it perfect for applications such

2-Stainless Steel

Stainless steel is another popular type of steel that has a wide range of uses. It is composed mainly of chromium and nickel, which gives it high levels of corrosion resistance and durability.

This makes stainless steel an ideal material for use in kitchenware, medical equipment, and even jewelry.

It is also commonly used in the construction industry, as it has excellent strength and can be used to create structures that are both durable and aesthetically pleasing.

Stainless Steel types

When it comes to stainless steel, there are three main types: Austenitic, Ferritic and Martensitic.

Austenitic Stainless Steel

Austenitic stainless steel is the most common type of stainless steel used in a variety of applications due to its excellent corrosion resistance and strength.

It is composed mainly of chromium and nickel, with other elements such as molybdenum and nitrogen added for additional corrosion resistance.

Ferritic Stainless Steel

Ferritic stainless steel has a similar composition to austenitic but with lower levels of chromium and nickel. This makes it less resistant to corrosion than austenitic but more cost-effective. It also has a higher magnetic permeability compared to austenitic.

Martensitic Stainless Steel

Martensitic stainless steel is a type of stainless steel that has a higher level of carbon compared to the other two types. This gives it superior strength and hardness, making it an ideal choice for applications such as cutlery and medical implants.

However, it is also more prone to corrosion than austenitic or ferritic stainless steel.

The above are just some of the most common types of steel available today. Each type has its own unique properties which make them suitable for different applications.

It’s important to choose the right type of steel for your needs in order to ensure you get the best results from your project!

With so many different types of steel available, you’re sure to find what you need.

3-Alloy Steel

Alloy steel is a type of steel that combines two or more metals together in order to achieve specific properties. The most common alloy steels include stainless steel and carbon steel, but there are many other types available as well.

Alloy steels are often used in applications where specific characteristics are needed such as strength, corrosion resistance, or malleability.

Alloy Steel types

When it comes to alloy steel, there are four main types: Nickel-chromium-molybdenum (NiCrMo), Low Alloy Steel, High Strength Low Alloy Steel and Tool Steel.

Nickel-chromium-molybdenum (NiCrMo)

This type of alloy steel is composed mainly of nickel, chromium and molybdenum which gives it excellent resistance to corrosion as well as good strength. It is often used in the oil and gas industry for components that require strength and corrosion resistance.

Low Alloy Steel

Low alloy steel combines two or more metals together but with lower levels than those found in NiCrMo. This makes it less resistant to corrosion than NiCrMo but still able to achieve good strength.

Low alloy steel is often used in the automotive industry for parts such as chassis and suspension components.

High Strength Low Alloy Steel

This type of steel combines two or more metals together, with a higher level than that found in low alloy steel, giving it increased strength while still being resistant to corrosion.

It is commonly used in construction applications due to its superior strength and corrosion resistance.

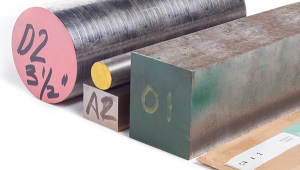

4-Tool Steel

Tool steel is another important type of steel that has been around for centuries. It is composed mainly of iron (which makes up about 95-98% of its composition) and small amounts of other metals such as carbon, chromium, molybdenum, and tungsten.

Tool steel is a type of alloy steel that is specifically designed for use in tools and cutting applications. It has good wear resistance, excellent strength, and good toughness which makes it ideal for applications where precision is required.

It is also often used in the medical industry for surgical instruments and implants.

Tool steel is extremely durable and can be heat-treated to increase its strength further. It is an ideal material for use in tools such as drills, saws, hammers, chisels, files, and wrenches.

Tool steel types

There are many different types of tool steel available, each with its own unique properties. Some of the most common types include:

High Speed Steel (HSS)

This is a type of tool steel that is composed mainly of molybdenum and tungsten which gives it excellent wear resistance and strength. It also has good heat-treatability making it ideal for applications such as drilling and milling.

Powdered Metal Steel

This type of tool steel is made by mixing iron powder with other metals in order to form a homogenous material. It has excellent corrosion resistance, toughness, and wear resistance while still being cost effective.

Shock Resistant Steel

This type of steel is composed of molybdenum and chromium which gives it high temperature strength as well as excellent shock resistance. It is often used in applications such as punches, dies, and cutting tools.

No matter what type of steel you’re looking for, there’s sure to be a variety that fits your needs! Be sure to research all the different types available in order to make an informed decision on which one will work best for your project. Good luck!

5-High-Speed Steel

High-speed steel (HSS) is a type of tool steel that contains high levels of tungsten. This makes it incredibly strong and resistant to wear and tear at high temperatures.

This makes it the material of choice for many applications where high performance is required such as drill bits, taps, milling cutters, and reamers.

High speed steel types

There are several types of high speed steel available, each with its own unique properties. These include:

M2 Steel

This is a type of HSS that has excellent wear resistance and heat treatability. It is often used in applications such as cutting tools, drill bits, and punches.

M4 Steel

This type of HSS is composed mainly of tungsten and vanadium which gives it superior strength and toughness at higher temperatures. It is commonly used in the aerospace industry for turbine blades.

M7 Steel

This type of high-speed steel contains molybdenum which increases its hardness while still remaining tough enough to resist shock loading. It can be found in applications such as circular saw blades, reamers, and end mills.

High-speed steel is an incredibly versatile material that can be found in a variety of applications. Be sure to research the different types available so you can make an informed decision on which one will work best for your project. Good luck!

if you are interested to Read about Types of Steel Click here

Conclusion

As you can see, there are many different types of steel with their own unique properties and applications. Whether you need a strong and durable material for industrial use or a corrosion-resistant material for kitchenware, there is sure to be a type of steel that meets your needs.

No matter the application, it’s important to choose the right type of steel in order to ensure optimal performance and quality.

Hopefully, this blog post gave you an insight into some of the most common types of steel and how they are used in various industries today. Thanks for reading!