Contents

Cranes are perhaps one of the most fascinating machines in existence. They tower over us, appearing almost otherworldly with their long necks and legs. And yet, they play a vital role in our world, helping to build the infrastructure that supports our modern way of life.

In this blog post, we’ll take a closer look at these incredible machines, exploring how they work and what makes them so special.

Cranes are one of the oldest and most popular types of construction equipment. They come in a variety of sizes and configurations, each designed for a specific purpose.

Here we discuss the top 19 types of cranes and their uses:

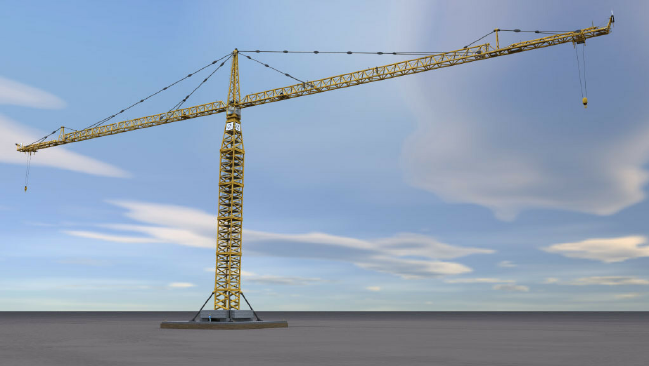

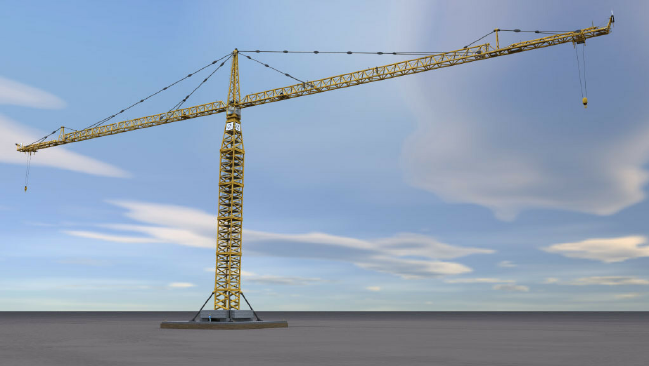

1-Tower Crane

Tower cranes are a common sight on construction sites and are ideal for lifting heavy loads at tall heights. They have large legs and tall towers, which allow them to reach high into the sky when in use.

2-Overhead Crane

Overhead cranes are most commonly found inside warehouses or factories, where they can be used to move materials from one area to another without disrupting floor space or other operations going on below them.

3-Crawler Crane

Crawler cranes have long tracks underneath them that enable it to move around a construction site with ease and stability. They come in various sizes and can lift extremely heavy weights (up to 800 tons).

4-Rough Terrain Crane

Rough terrain cranes are the go-to choice for off-road and harsh terrain construction sites, as they use a four-wheel drive system to move over slippery or muddy surfaces with ease.

5-Floating Crane

Floating cranes are designed to operate on water and can be used for dredging, harbor cleaning and heavy lifting operations in port areas.

6-Shipyard Gantry Crane

Shipyard gantry cranes are used to load cargo onto ships at dockside locations. They have large spans that allow them to reach out over the entire length of a ship’s hull in order accommodate loading and unloading tasks.

7-Telescopic Handler Crane

Telescopic handler cranes are smaller machines that are used to lift and move materials around a construction site. They come with extendable arms, which allow them to reach higher heights and transport more weight than conventional cranes.

Telescopic handler cranes are multi-functional machines that can be used for a range of different tasks, from lifting materials at height to placing them in hard to reach areas.

They come with adjustable arms which allow them to reach higher heights than other crane types and their powerful engines provide the operator with precise control when lifting heavy weights.

8-Boom Truck Crane

Boom truck cranes are mounted on the back of trucks, making them incredibly mobile and easy to transport from one location to another. They have telescoping booms with adjustable jibs, allowing for precise placement of heavy loads at height.

9-Industrial Overhead Crane

Industrial overhead cranes (also known as bridge cranes) are large crane systems installed inside industrial settings for the purpose of lifting and moving heavy materials within a confined space.

10-Knuckle Boom Crane

Knuckle boom cranes are a type of articulating crane that is highly versatile and can be used for a wide range of tasks, including loading and unloading materials onto boats or trucks.

11-Jib Crane

Like overhead cranes, jib cranes are usually found inside factories and warehouses where they help move materials around the facility with precision and speed. They have an arm attached to a wall or column which allows them to rotate around their base in order to reach all areas of the facility.

12-Gantry Crane

Gantry cranes are large crane systems that span a wide area and usually feature two vertical posts for stability. They can be used for heavy lifting operations and are often found on docks, railroads and construction sites.

13-Wall Mounted Jib Crane

Wall mounted jib cranes are similar to conventional jib cranes but they’re designed to be attached directly onto the wall of a building or structure, rather than being suspended from an overhead beam.

14-Monorail Crane

Monorail cranes are crane systems that use an overhead trolley system to move materials around a facility with speed and precision. They come in both single and double girder designs and can be used for both indoor and outdoor operations.

15-Tower Crane

Tower cranes are large cranes that are usually found on construction sites, where they’re used to lift heavy materials up to great heights. They have tall towers that allow them to reach high into the sky while in use and they come with a range of features, such as telescoping booms, adjustable jibs and more.

16-Container Handler Crane

Container handler cranes are designed specifically for loading and unloading cargo containers from ships at dockside locations. They have powerful engines capable of lifting heavy weights quickly while also being able to precisely maneuver cargo containers in tight spaces.

17-Pick And Carry Crane

Pick and carry cranes are highly agile machines that can be used to lift, move and place materials around a construction site with ease. They come with adjustable arms which allow them to reach higher heights than other crane types and they’re easy to transport from one location to another.

18-Aerial Platform Crane

Aerial platform cranes are designed for working at height and usually come with an extendable boom arm which provides the operator with a safe working area when suspended in the air. They have powerful engines capable of lifting heavy weights quickly and accurately.

19-Boom Lift Crane

Boom lift cranes are similar to aerial platform cranes but instead of having an extendable boom arm, they use hydraulic cylinders which provide the operator with a stable working platform at height.

They’re usually used in construction and maintenance applications where it’s necessary to reach high places quickly and safely.

All crane types have different capabilities, benefits and safety features making them suitable for specific applications.

Careful consideration should be taken when choosing the right type of crane for a project, as safety and efficiency should always be at the forefront of any operation.

When in doubt, it’s best to consult with a professional who can assess your requirements and recommend the right crane for you.

It’s also important to remember that all cranes need to be inspected, maintained and operated by certified personnel in order to meet safety standards.

Regular inspections should always be carried out on a regular basis in order to ensure that the crane is safe and functioning properly before use.

This will help prevent accidents and costly downtime. Finally, never attempt to operate a crane if you aren’t qualified or experienced enough; instead, hire a professional crane operator who is trained and certified to do so safely.

Despite their intimidating size and shape, these machines actually make our lives easier by helping us construct buildings faster and more efficiently than ever before.

Whether you’re on a construction site, in a factory or at a port, you’ll almost certainly encounter these incredible machines at work. So the next time you see a crane in action, take some time to appreciate their contributions to our modern way of life.

if you are interested to Read about Types of Bridges Click here

Conclusion

In conclusion, cranes are an essential piece of machinery for many industries. They offer a range of features that make them suitable for lifting and transporting heavy items in difficult environments.

However, it is important to remember that they must be inspected, maintained and operated by certified personnel in order to meet safety standards.

Additionally, never attempt to operate a crane if you do not have the required experience or qualifications. By following these guidelines and taking proper precautions when using cranes, you can ensure that jobs are completed safely and effectively.

Thanks for reading! Enjoy your day!